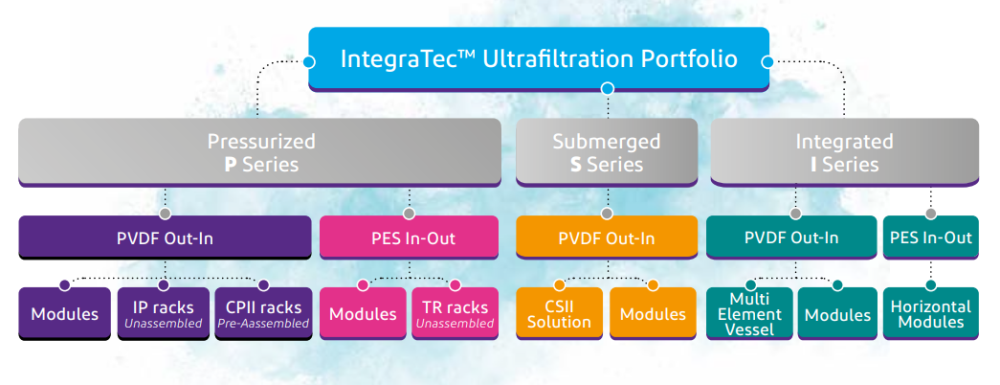

To continue its progress in the water industry, DuPont™ has launched its new harmonised UF product portfolio and combined the heritage DuPont™ UF, heritage inge® UF and heritage Memcor® UF brands under one new strong brand - DuPont™ IntegraTec™ Ultrafiltration.

Robust, easy to clean PolyCera membranes extend the range of ultrafiltration and nanofiltration performance beyond conventional ceramic and polymeric membranes.

PolyCera® is a new polymeric material, supplying ceramic like robustness with the flexibility of a polymeric membrane.

PolyCera membranes offer a unique combination of extreme hydrophilicity, permeability and robustness.

PolyCera membranes were developed to extend the range of polymeric membrane filtration to tackle the most challenging applications, delivering stable performance even under extreme pH, temperature, fouling and chemical conditions. This means low energy and high sustainable flux operation with extended membrane life, maximum system uptime, and minimal residual waste to manage.

PolyCera membranes are designed as spiral wound elements in configuration of 1,8“, 4“ and 8“. They are available as ultrafiltration (10 kDa, 70 kDa, 100 kDa, 250 kDa and 500 kDa) and nanofiltration (500 Da).

The use of feedspacer up to 120 mil offers a wide range of applications even with very high solids. The PolyCera elements are 100% backwashable.

The elements can be operated in vertical and horizontal mode and fit into standard RO pressure vessels.

Hydro

Typical applications

- Water-/ waste water treatment

Digestate treatment

Laundry waste water

Pulp and paper

- Fodd & beverage

- Dairy

- Process water treatment

- And many more

Titan

Industrial applications

- Water-/ waste water treatment

- Process water treatment with special requirements like

- uvm

- Titan Off-Shore

Off-Shore applications like

- Produced Water

- Prefiltration „Sulfate Removal“

- Application with special request for

BTEX stability

High oil resistance (oleophobic)

Wide operating pH range

Wide operating temperature range

High chlorine stability (up to 100.000 ppmh @ pH 11)- uvm

DuPont™ Ultrafiltration

The DuPont™ ultrafiltration is based on a PVDF membrane with a separation limit of 0.03 µm (100 kDa). What is special is the filtration mode from the outside to the inside. The membrane is highly resistant to chemicals, very easy to clean and has low operating costs. It is used for preliminary filtration upstream of reverse osmosis systems, drinking water treatment and waste water treatment. The SFP/ SFD module series has been in operation for many years and has a large number of references worldwide. The modular module system IntegraPac™ offers a scalable solution for your ultrafiltration rack. Thanks to the intelligent design of the end caps, which simultaneously serve as collectors, the rack can be set up in the smallest of spaces. The system is variable and can be adapted to the requirements. The new IntegraFlo™ module design features a membrane area of up to 102 m². And this with a diameter of 219 mm (8") and a length of 2,359 mm (80"). This module covers the need for cost optimization in water and waste water treatment plants.

Manual

Ultrafiltration modules

The DuPont™ ultrafiltration product range offers modules in various sizes and for applications in process and drinking water. The modules range from 33 m² up to 77 m³ membrane area.

The SFP product range is used in industrial water treatment and the SFD product range in drinking water treatment.

Ultrafiltration industry

The SFP product range of the DuPont™ ultrafiltration is used in industrial water treatment. Modules with 33 m², 51 m² and 77 m² are available. All contain the PVDF membrane with a separation limit of 0.03 µm (100 kDa) and the flow from the outside to the inside.

Ultrafiltration drinking water

The SFD product range of the DuPont™ ultrafiltration is used in water treatment for drinking water production. Modules with 33 m², 51 m² and 77 m² are available. All contain the PVDF membrane with a separation limit of 0.03 µm (100 kDa) and the flow from the outside to the inside.

The DuPont™ ultrafiltration SFD modules have the American drinking water approval NSF/ANSI 61.

DuPont™ IntegraPac

The modular module system DuPont™ offers a scalable solution for your ultrafiltration rack. Thanks to the intelligent design of the end caps, which simultaneously serve as collectors, the rack can be set up in the smallest of spaces. The system is variable and can be adapted to the requirements. The IntegraPac™ is available for industrial and drinking water treatment applications

IntegraPac™ industry

The modular module system DuPont™ offers a scalable solution for your ultrafiltration rack in industrial water treatment. Thanks to the intelligent design of the end caps, which simultaneously serve as collectors, the rack can be set up in the smallest of spaces. The system is variable and can be adapted to the requirements. The module sizes are available with 51 m² and 77 m² membrane area. An IntegraPac™ ultrafiltration rack with 22 modules offers a membrane area of up to 1694 m² and can process more than 110 m³/h (@ Flux 65 lmh)

IntegraPac™ drinking water

The modular module system DuPont™ offers a scalable solution for your ultrafiltration rack in drinking water treatment. Thanks to the intelligent design of the end caps, which simultaneously serve as collectors, the rack can be set up in the smallest of spaces. The system is variable and can be adapted to the requirements. The module sizes are available with 51 m² and 77 m² membrane area. An DuPont™ ultrafiltration rack with 22 modules offers a membrane area of up to 1694 m² and can process more than 110 m³/h (@ Flux 65 lmh).

The DuPont™ ultrafiltration SFD modules have the American drinking water approval NSF/ANSI 61.

If you have any questions or requests, you can simply write to us using the form.